Your cart is currently empty!

Earn 2% Cashback + Free Delivery

Earn 2% Cashback + Free Delivery

Protective Finishing refers to value-added operations that are performed after the ink has been applied to the paper.

1. Laminate

This is the process of applying a thin layer of plastic to paper or card sheets to enhance and protect the printed surface.

Whilst forming a protective coating over the print, it does not provide the same level of protection as gloss lamination and can be prone to scratching and fingerprints especially where folding is involved.

Gloss Laminate: Gloss is more high profile, it adds a high gloss sheen often used on brochure covers, menus, magazine covers or presentation folders. It is definitely the high impact option.

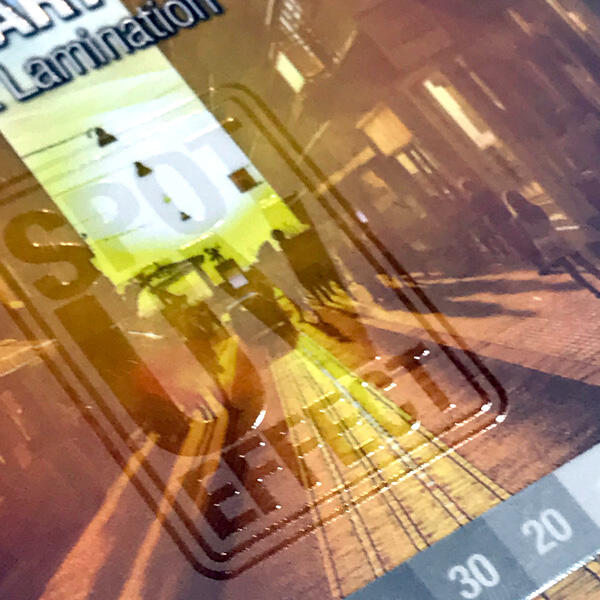

2. Spot UV

Spot UV refers to the application of this UV Coating to a specific area (or areas) of a printed piece rather than coating the entire surface. Used primarily as a design technique, Spot UV is a creative way to add depth and contrast through varying levels of sheen and texture.

3. Waterbased Varnish

Waterbased (or Aqueous) Varnish is a water-based coating that is applied to the press sheet. This varnish process allows the resulting product to look as if it “pops” more off of the page, and also protects the product from scratches, sticky fingerprints, scuffs and other marks that could deter from its vibrant looks.

4. UV Varnish

UV coating is a clear compound that is applied to paper wet, then instantly dried by ultraviolet light (UV coating is short for ultraviolet coating). It gives a gloss reflective finish.